China New Product NXK0382-500 brushless motor for dry vacuum cleaner Export to Botswana

Short Description:

China New Product NXK0382-500 brushless motor for dry vacuum cleaner Export to Botswana Detail:

Specifications:

Voltage: 220V, 50Hz/60Hz

Fan System: Through flow,1-stage

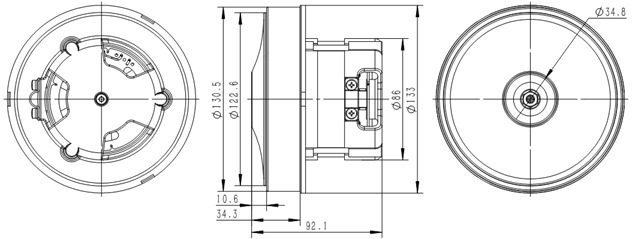

Diameter:φ133mm

Weight: 1.43kg

Insulation: F

Feature: Brushless, High efficiency, energy saving, environmental friendly, long life.

Typical Performance

|

Sealed Orifice |

Orifice Loading |

Orifice Loading |

Max. Eff. |

|

| Orifice (mm) |

0 |

50 |

23 |

16 |

| Vacuum Pressure (kPa) |

17.81 |

1.25 |

3.86 |

6.54 |

| Air Flow (m3/min) |

0 |

2.191 |

1.747 |

1.203 |

| Air watt (Watt) |

0 |

45.65 |

112.41 |

131.11 |

| Speed (rpm) |

31250 |

21150 |

21140 |

21160 |

| Input Power (Watt) |

431.04 |

499.16 |

474.60 |

423.88 |

| Efficiency (%) |

0 |

9.16 |

23.68 |

30.94 |

Outline Drawing

Product detail pictures:

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for China New Product NXK0382-500 brushless motor for dry vacuum cleaner Export to Botswana, The product will supply to all over the world, such as: Colombia , Ireland , Tunisia , With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

To replace the main brush motor on bObsweep Standard, you will need a Phillips head screwdriver, a flat head screwdriver, and a new main brush motor.

Before starting any repair on Bob, turn his side power switch OFF and remove his dustbin.

Then, flip Bob over onto a flat surface and remove his main brush using the flat head screwdriver.

Keep all removed screws and parts safely aside, as they may be needed for later reassembly.

Use a Phillips head screwdriver to remove the 7 screws on Bob’s underside that hold him together.

One screw on each side of the front wheel. One screw to the right of the main brush motor.

One screw on each side of the dustbin. The final screw is in the brush compartment.

Bob’s cover is no longer secured, so hold the top and bottom together as you carefully flip him back onto his wheels.

Grip Bob’s cover from the back and lift up to expose the mainboard.

Slide the power inlet down and tuck it somewhere safe to avoid compressing its wires.

To detach Bob’s cover completely, disconnect 4 circuit plugs:

Two at the lower edge of the mainboard, near the wheels.

And two more at the top edge, near the bumper.

Bob’s cover is now completely detached and can be set aside for the rest of the repair.

The main brush motor is found on Bob’s left side, in front of the left wheel. Grip the motor and slide it up.

Then, grip the tab on the motor’s circuit plug and pull up to remove it from the mainboard.

Next, connect the new main brush motor to the mainboard. Push down firmly to ensure a secure connection.

Align the new motor’s edges with the indentations on Bob. It should easily slide straight down when lined up correctly.

Once in place, you’re ready to close Bob.

Reattach all 4 circuit plugs connecting Bob’s cover to the mainboard.

2 connect to the top edge of the mainboard, and 2 more that connect to the bottom edge.

Remember to slide the power inlet back into its space on Bob’s cover.

Align the cover’s edges precisely. Then, flip Bob over onto a flat surface.

Ensure that no wires are compressed in the main brush compartment or visible at the edges of the bumper.

If so, take a step back and lift the cover to tuck the wires into the appropriate spaces.

Once the wires are all safely tucked away and Bob’s cover is aligned properly, reinstall all 7 screws previously removed from Bob’s underside.

Install the main brush and dustbin before your next use and Bob is completely re-assembled.

Turn the side power switch back on and congratulations! You’ve just replaced Bob’s main brush motor. Happy cleaning!

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.