Hot sale good quality NXK0282-1000-1P brushless motor for vacuum cleaner to America Factory

Short Description:

Hot sale good quality NXK0282-1000-1P brushless motor for vacuum cleaner to America Factory Detail:

Specifications:

Voltage: 220V, 50Hz/60Hz

Fan System: peripheral by pass, 1- stage

Diameter:φ145mm

Weight: 1.95kg

Insulation: F

Feature: Brushless, High efficiency, energy saving, environmental friendly, long life.

Typical Performance

|

Sealed Orifice |

Orifice Loading |

Orifice Loading |

Max. Eff. |

|

| Orifice (mm) |

0 |

50 |

23 |

23 |

| Vacuum Pressure (kPa) |

18.98 |

2.81 |

7.65 |

7.65 |

| Air Flow (m3/min) |

0 |

3.597 |

2.591 |

2.591 |

| Air watt (Watt) |

0 |

168.43 |

330.34 |

330.34 |

| Speed (rpm) |

- |

- |

- |

- |

| Input Power (Watt) |

1037.98 |

994.94 |

952.62 |

952.62 |

| Efficiency (%) |

0 |

16.94 |

34.68 |

34.68 |

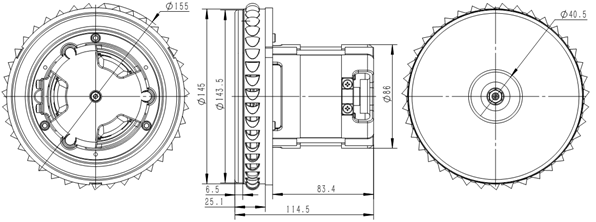

Outline Drawing

Product detail pictures:

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for Hot sale good quality NXK0282-1000-1P brushless motor for vacuum cleaner to America Factory, The product will supply to all over the world, such as: Costa Rica , Uzbekistan , Tuvalu , Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Brushless motor , rotor and sensor shimming.

Correct shimming for rotor to sensor timing.

Shim the rotor as close as possible to the sensors.

Shim out the end float to minimum

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.