Trending Products NXK70 serie brushless motor for Household Hand Dryer Supply to Latvia

Short Description:

Trending Products NXK70 serie brushless motor for Household Hand Dryer Supply to Latvia Detail:

Specifications:

Voltage: 220V, 50Hz/60Hz

Fan System: Though flow, 1-stage

Diameter:φ105mm

Weight: 0.94kg

Insulation: F

Feature: Brushless, High efficiency, energy saving, environmental friendly, high speed.

Typical Performance

|

Sealed Orifice |

Orifice Loading |

Orifice Loading |

Max. Eff. |

|

| Orifice (mm) |

0 |

50 |

23 |

23 |

| Vacuum Pressure (kPa) |

5.81 |

1.39 |

3.60 |

3.60 |

| Air Flow (m3/min) |

0 |

2.459 |

1.718 |

1.718 |

| Air watt (Watt) |

0 |

56.56 |

103.29 |

103.29 |

| Speed (rpm) |

- |

- |

- |

- |

| Input Power (Watt) |

115.43 |

357.30 |

346.67 |

346.67 |

| Efficiency (%) |

0 |

15.90 |

29.77 |

29.77 |

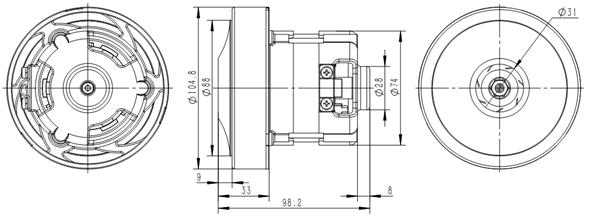

Outline Drawing

Product detail pictures:

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for Trending Products NXK70 serie brushless motor for Household Hand Dryer Supply to Latvia, The product will supply to all over the world, such as: Czech Republic , Iran , Libya , With the advanced workshop, professional design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our products are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

https://www.ereplacementparts.com/throttle-cable-assembly-p-283347.html Click here for more information on this part, installation instructions and more.

This particular throttle cable is specific to Ryobi manufactured brands, including Ryobi, Troy-Bilt, Yard Man, Bolens and MTD. To find a throttle cable specific to your model, visit eReplacementParts.com.

If your string trimmer is showing any of these symptoms; replacing the throttle cable assembly could solve your problem:

1) Throttle not functioning

2) No tension in throttle lever

3) Throttle cable loose in housing

4) Throttle cable disconnected

5) Throttle cable linkage (on ends) broken

eReplacementParts.com part number: 791-182068

Tools used for this repair/replacement:

1) Torx / Phillip’s drivers

2) Standard screwdriver

Get model-specific repair help from eReplacementParts.com. Learn how to troubleshoot, diagnose and repair your power tools and equipment with illustrated instructions, hundreds of step-by-step repair videos, and our DIY forum. If you have a power tool or appliance problem, we can help. https://www.ereplacementparts.com/articles-c-8873.html

[ VIDEO TRANSCRIPT ]

Hi, I’m Mark from eReplacementsParts.com. In this video, I’m going to show you how to replace the throttle cable on a Ryobi Trimmer. The throttle cable is the linkage between the throttle trigger and the carburetor. A common problem with the throttle cable is that eventually, the end will fatigue and then, break off. And it’s also common for the cable to get kinked and it’ll no longer operate smoothly. Replacing the throttle cable is easy to do, and I’m going to show you how.

I’ll begin by moving the accessory from the motor shaft. The handle assembly is secured with five screws plus on anti-rotation screw. I’ll split the two-halves by removing the two screws. Now remove the trigger and the trigger spring.

With the trigger removed, now we can go ahead and pull the opposite half of the handle assembly away from the throttle cable. Now remove the back cover from the engine. Now, we have access to the carburetor and the throttle cable. While it is possible to remove the throttle cable from the carburetor’s linkage without removing the carburetor, it’s very easy to accidently break the cast end on the end of the throttle cable. So I’ll go ahead and remove the two screws that secure the carburetor to the engine. Now I can pull the carburetor away and twist it up while removing the throttle cable.

Now, I can remove the throttle cable from the engine. The large end of the throttle cable needs to pass through the larger hole in the carburetor base. And once it’s through I can pull the throttle cable away from the engine.

Now, I’ll install the throttle cable. First, the throttle cable passes through the opening in the housing. Then, the large end on the throttle cable passes through the large hole in the back of the carburetor plate. As we do this, there’s a slit on the underside of this tube and that slit will accept the throttle cable. And then, I just slide the throttle cable housing inside of that tube.

Now, I’ll reinstall the throttle cable back on to the carburetor’s throttle linkage. And I’ll secure the carburetor, as well as the choke plate, with the screws. As I tighten the upper screw I want to make sure I have the choke plate lined up, as well as the wavy washer, so it doesn’t get pinched by the screw.

And now, I’ll reinstall the rear cover with the air filter. Now, I’ll slide the throttle cable into the side of the trigger grip. And I’ll bring the cable in until it bottoms out on the shoulder, like that.

Now, I’ll install the throttle trigger. The alignment between the trigger and the throttle cable is important. The end of the cable has a Z-shape to it. You need the fat part of that Z, or the part that’s in-line with the cable, to be on top of the trigger. So, I’ll align the trigger with the throttle cable and slide it through. And again, I just need to make sure that this fat portion is on top of the trigger when it mounts into the handle.

Now, I’ll install the throttle trigger spring. It wraps around to the back of the throttle trigger, lines up with the hole on the trigger, and then drops into the housing. As I slide the trigger and spring down into the housing, I want to pull the spring back so it fits just in front of the plastic rib, like that.

Now I can install the other half of the throttle handle. I just want to make sure everything’s aligned: the spring, the throttle trigger and the throttle cable up against the shoulder as I slide the two-halves of the handle together.

I’ll go ahead and secure the handle with the five screws. Now install the anti-rotation screw for the trigger handle assembly.

[ END TRANSCRIPT ]

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.